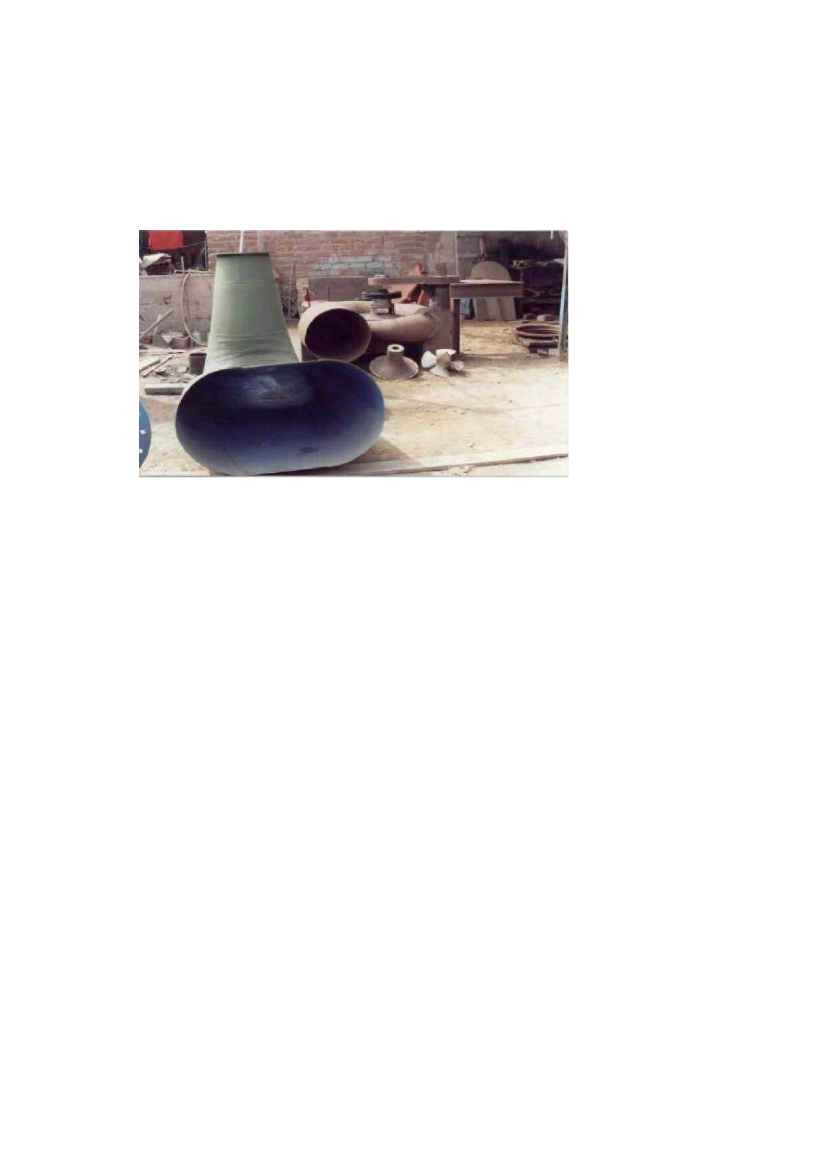

1.6 Suction tube

This is the component responsible for channelling the water after it passes by

the turbine wheel, as far as the outlet channel. The suction tube is used on

reaction-type turbines. (Fig. 3)

Figure 3: Suction tube manufactured from sheet steel

1.7 Transmission

This system is responsible for transmitting the movement and mechanical

power of the turbine to the generator. As a result of design conditions, the

speed of the turbine (900 r.p.m.) does not coincide with the speed of the

generator (1800 r.p.m.), meaning that the speed needs to be stepped up. In

this case a flexible transmission system is employed, using belts and pulleys:

3 trapezoidal belts, a guided 8-inch diameter pulley on the generator axle

and a 16-inch diameter drive pulley fitted to the turbine axle.

1.8Valve

The valve serves to control the flow of water. For this axial turbine a 600 mm

diameter gate-type valve has been produced, to be fitted upstream of the

intake of water into the turbine. (Fig. 4)

1.9Dresser coupling

This device serves to connect the turbine to the pressure pipes, and is

therefore referred to as a mounting joint. This